Эффективное улавливание и нейтрализация вредных веществ, снижение неприятного запаха

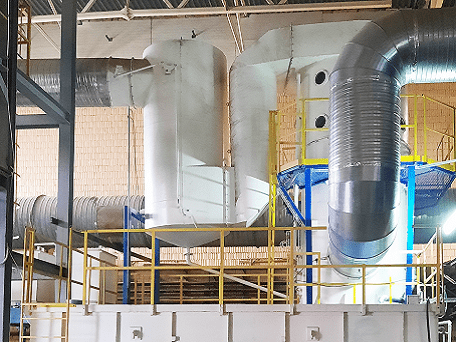

Абсорбционно-биохимические установки предназначены для мокрой промышленной очистки вентиляционного воздуха от летучих органических (ЛОС) и некоторых неорганических соединений, сопутствующих взвешенных и смолистых веществ

АБХУ очищает промышленный вентиляционный воздух до нормативов ПДВ

ГАРАНТИРОВАННОЕ РЕШЕНИЕ ПРОБЛЕМЫ ВЫБРОСОВ

В основе – многолетняя научно-исследовательская работа и мониторинг эксплуатации АБХУ на предприятиях

Экономичная

низкие эксплуатационные расходы и минимальное техническое обслуживание

ЭКОЛОГИЧНАЯ

Эффективная

Безопасная

отсутствие химических реагентов, кислот и щелочей. Пожарная безопасность

Все больше предприятий выбирают АБХУ

В связи с наличием в вентвоздухе конденсационных и взвешенных веществ

АБХУ – ЕДИНСТВЕННОЕ ФУНКЦИОНАЛЬНОЕ РЕШЕНИЕ

Для большинства предприятий

- Изготовление фанеры, ДСП, плит МДФ/ХДФ, OSB, синтетических клеящих смол, импрегнированной бумаги

- Получение форм и стрежней по технологиям Cold-box-amin, Альфа-сет процессы

- Заливка, охлаждение и выбивка литейных форм

- Изготовление теплоизоляционных плит из стекловолокна или базальта

- Пропитка полимерами тентовых, кордных и фильтровальных материалов

- Производство олифы

- Окрасочные камеры

- Изготовление изделий из пластмассы методом литья, горячего прессования, экструзии

- Вторичная переработка полиэтиленовой пленки

Проекты

КАКИЕ ЗАДАЧИ РЕШЕНЫ С ПОМОЩЬЮ АБХУ

Комплексное решение задачи промышленной очистки вентвоздуха от ЛОС

ПОСТАВКА ОБОРУДОВАНИЯ В ЛЮБУЮ СТРАНУ СНГ

Бесплатная консультационная поддержка в течение всего срока эксплуатации оборудования